Determining the digital maturity level of product development - why?

How does a review of the digital maturity level of product development help with digitalization?

Digital maturity level for guidance

Digital transformation plays a key role in the realignment of traditional industries. Challenges such as individual customer requirements, shorter market cycles, and sustainability requirements can no longer be met without modern technologies. To master these demands, companies need to increase the digital maturity level of their product development.

A digital maturity level describes the degree to which digitalization has progressed in a company. This involves an analysis of the status quo. In terms of product development, it provides conclusions about the strengths and weaknesses of the development organization. The result is an overview that enables logical strategic planning.

Maturity models do not focus on individual technologies or processes. They evaluate an organization as a whole and show how companies are gradually improving in the examined area.

A breakdown of three typical, interrelated target dimensions in the digitalization of product development shows why such an analysis is worthwhile:

- Connecting product development

- Connecting the company systems

- Connecting the company

1. Connecting product development

Effective alignment is essential for cross-team and cross-disciplinary engineering. Since every design team today uses its own software tools, data silos are created very quickly, making it difficult to exchange information. This is where companies should start first.

The main target is to link all software solutions used in design. This primarily concerns the authoring systems (e.g. CAD, CAE) and Product Data Management (PDM).

Suitable for networking are centralized platforms that synchronize and logically connect data and systems. Companies benefit from a data library (single source of truth) that supplies reliable, consistent information and documents.

If everyone in the design team has access to such a database, this increases the quality of collaboration. Efforts to search for product data is eliminated and sources of error vanish.

In addition, the individual teams can more easily evaluate how their ideas impact other areas (mechanics, mechatronics, electronics, etc.). They gain more space for creativity and make decisions that affect other departments faster and more profoundly.

2. Connecting the company systems

Product development affects many departments within a company, whether it’s procurement, sales, materials management or production. Here too, there are system breaks in digital communication that unnecessarily delay development projects.

That is why connectivity is not only important at the design level. The planning and execution tools (ERP, production planning and control, etc.) should also be connected to the platform that links their system world. This gives all departments access to centralized informationsuch as approved parts, order status, delivery dates, stock levels or purchase prices.

The transparency created by connecting heterogeneous systems improves communication and coordination in interdisciplinary projects. As a result, the speed of product development increases. At the same time, networking positively affects product quality, the reliability of delivery schedule planning, and customer satisfaction.

3. Connecting the company

Connecting the IT landscape links product development to all parts of the company. The outcome is a digital thread that enhances collaboration across departmental and company boundaries. New technologies and functions can be flexibly added to this ecosystem thanks to the platform logic.

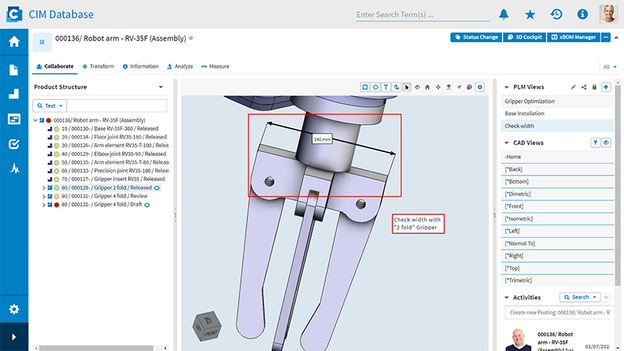

For example, CONTACT's PLM software CIM Database Cloud Innovate helps companies with a high level of digital maturity to increase their speed and innovative strength. It provides functions for

- rights and role concepts,

- change management,

- article management,

- Bill of Materials (BoM),

- the management of product portfolio,

- the modeling of product variables and

- the calculation of product costs.

Features like these are helpful for modern development methods, sometimes even fundamental. Development teams do not operate in isolation but benefit from the exchange with other departments in the company.

If the prerequisites for this exist on both the system and process side, customer and market requirements can be taken into account systematically and earlier in the development process. Flexibility, productivity, and speed of product development increase.

Summary

For manufacturing companies, digitalization is increasingly becoming a precondition for their market participation. Given the rising complexity of interdisciplinary development projects, product development is a key aspect of this.

Skilfully orchestrated, digital initiatives in this area not only ensure lower development costs and times. They can also increase process efficiency, customer focus, and the ability to innovate and make decisions. At the same time, companies can react more proactively to new trends and requirements in their industry.

To realize these benefits, companies need to take a strategic approach. The first important step is to review the status quo. A maturity level analysis is a great help in planning the logical next steps and starting the change at the points where the greatest added value for the organization is created. The result is a digitalization roadmap with suitable measures that companies can gradually implement.

Where do you currently rank?

An analysis of the current status generates the greatest added value if your company is asking the right questions. We have therefore created a maturity level analysis based on the project experience of our PLM experts. It helps you to assess the strengths and weaknesses of your development organization and draw the right strategic conclusions based on this.